Diagnosis Tool for Engine Control Units

Usually, diagnosis and service tools for engine control units

(ECU) are managed by very specialized, thus high-priced hardware diagnosis

boxes. The described application 'STEYR_diag', developed originally in LabVIEW™

6i, can achieve the same job with all features required by the automotive

industry. All that is needed is a simple PC (usually a notebook).

The major milestone was to distinguish the user level (from simple user to test

bench engineer) to adapt the user interface and available options. The basic

features, which are described below in more detail, are: automatically find port

and ECU, monitoring and displaying data, monitoring and clearing errors,

calibration of engine instruments, and logging data.

Program Features

'STEYR_diag' is a 32 bit Windows application that requires an operating

system Microsoft® Windows® 95B or higher. Processor speed should be at least

166 MHz, with 32 MB Ram and 20 MB free disc space. After automatically

installing the LabVIEW™ runtime engine, the main program is installed. An

initialization file, where each change of settings is stored, is created at

first run.

Due to the outdoor surroundings of possible places of action, each function can

be carried out just by hitting certain keys, no mouse is necessary. This is

especially useful, e.g., for checking boat engines aboard.

The following features are available in the main window.

Monitoring and recording

Various data like engine speed, oil temperature, booster pressure, etc. are

provided by the ECU. The data can be freely selected from the user interface and

are displayed as digital values and/or graphical instruments. The data can be

recorded with high sample rate and stored in a text-based format for further

evaluation. One x-axis as well as several y-axes can be selected for display in

a preview (XY graph). A special algorithm prevents from overwriting data

accidentally.

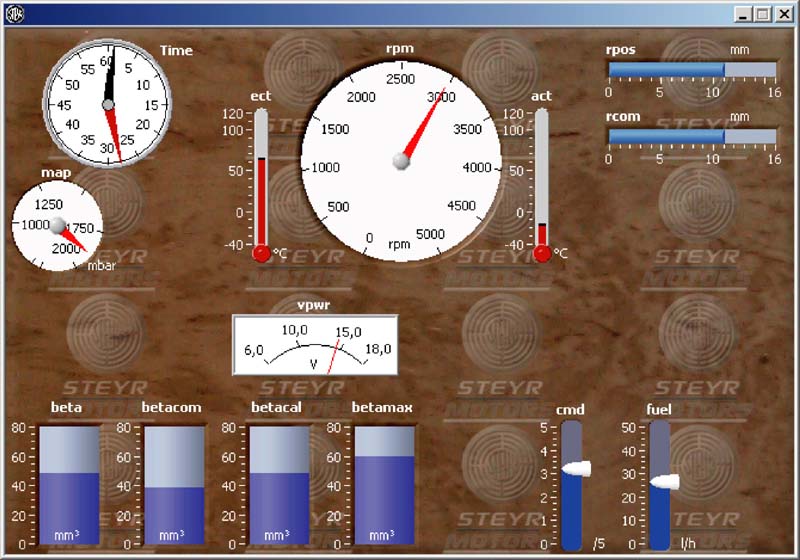

By pressing the 'Graphic' button in the main window, the display of a virtual

dashboard appears, see figure 1.

Figure 1 Virtual dash board in 'STEYR_diag'

Moving the cursor over the various instruments causes the popping up of tip

strips with additional information. The gauge will be displayed at the virtual

dashboard only if the corresponding channel is selected.

Showing errors stored in the ECU and clearing them

After entering the error handling subroutine, the window shown in figure 2

appears. The sample rate is lower. The error frame at the right bottom shows the

current errors which are listed, consisting of error code, error number, and the

reason/solution part. Different colors emphasize whether the error is obsolete

or actual.

On the left of the error frame there are check boxes for selecting and

deselecting a specific error. It is possible to trace one particular active

error; in this case a sound is generated while the program permanently tries to

clear the error. This is a useful tool as it allows to check cables or

connections at the engine until the sound is off.

The contents of the user interface will change according to

the selected program feature. However, the following information is found in

each subroutine window:

-On the bottom left of the frame in figure 2, the selected channels are shown,

-Additional information about the respective ECU, which is shown on the top

right,

-Information about the torque limiter can also be found in the main window.

The number of the function keys and their allocation on the top left is of

course depending on the subroutine.

Figure 2 Window of the error subroutine of 'STEYR_diag'

Loading several parameters

Parameters like user level, communication features, ECU memory addresses, etc.

are loaded from a file. The ECU memory addresses are encrypted. The parameter

file is secured by a special algorithm, which makes the file invalid as soon as

it was tampered.

Calibration of engine instruments

This submenu is for the calibration of speedometer, thermometer, and idle speed.

In this routine, an instruction message for further procedure pops up

corresponding to the respective selected instrument.

Automatically finding the interface and the type of the ECU

The connection of the ECU is established by an ISO-K / RS232 interface. The port

of the PC is found automatically as is the type of the ECU. This information is

shown on the top right corner.

Demo mode

If no ECU was detected during initialization of the program, the user can run a

demonstration to check out all features of the software. A prepared data set is

displayed with full functionality. So, clearing of errors, setting instruments,

logging, etc. can be evaluated.

User level

A rather broad spectrum of people with different knowledge and qualifications

are expected to use this program. They will consist, for example, of developers,

test bench engineers, sales persons, end-clients. Therefore, it is necessary to

provide different user authorizations to alter and operate this application for

these different levels.

Users with low authorization, e.g., will just have to start and stop data

logging. Selection of channels, storing location, file name, and so on, are

provided automatically. An engineer unlike, has the additional possibility to

select channels from a large pool. This person can select the sample rate as

well as preview of the data using various x-, and y-axis. Furthermore, the

supply of menu entries at higher user level is much larger. It may be forced a

certain port or ECU type to avoid time delay while automatically search or

specify file paths to easily run multiple configurations. It is also possible to

alter connection failure tolerance to run at higher sample rate.

However, menu options like selection of language or unit are available at all

levels. Since M1-engines are sold nearly all over the world, this feature is a

courtesy to the customer and sales representatives.

Conclusion

The easy-to-use, self-explaining design ensures a timesaving and hence

cost-effective diagnostics. A high flexibility of this tool can be reached with

LabVIEW™. It can be applied for all kinds of M1-engine types and at different

user levels from end customers up to developers. All this results in operational

safety and a simple, low-cost maintenance. In addition, features like safety

routines secure from unauthorized manipulation make it a powerful service und

client tool.